The Value of Part Assembly Solutions for OEMs

August 22, 2018

The “value added” service trend is showing no signs of slowing down these days. But how can you determine which metal fabrication partners are actually providing value, apart from those who only say they do?

Granted, the definition of “value added” can be dependent on the situation, but one area which is often overlooked is assembly. This manufacturing solution is provided when a metal fabricator not only cuts and mills all the parts for a sub-assembly, or even larger components, but they also put all the pieces together. In doing so, they can not only save an OEM time, but also money. Let’s take a deeper look at how a strategic metal fabricator can add value through its metal part assembly solution.

Value Add 1: Simplified Production

Value Add 1: Simplified Production

Let’s face it, while new technologies have helped designers and engineers, they have also added complexity to the production process. Even when the number of line items on a Bill of Material (BOM) has been cut back, tighter tolerances and more complicated assemblies have made production difficult to manage.

This is one area where a metal fabrication partner can come to the rescue. Beyond cutting, bending and welding, they can lend a hand with part assemblies. By doing so, they can identify mismatched parts earlier in the process and even work with engineers to revise builds when needed.

Value Add 2: Collaboration with the Design Team

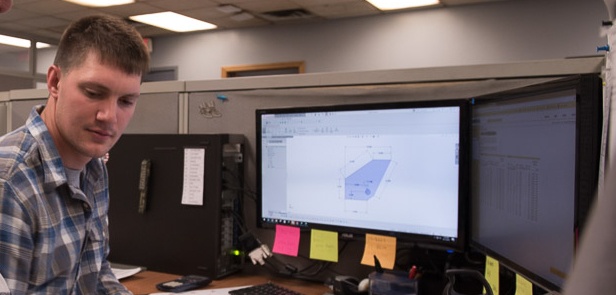

As mentioned, technologies, such as Computer-Aided Design (CAD), have created operational hurdles for most in the supply chain. This usually happens when designs are drafted with little or no input from the production team.

Sure, every OEM conducts small lot manufacturing and testing, but the problems occur when new models are put into full production. As such, having a strategic fabrication partner who can collaborate with the design team early in the planning process can be of great benefit to those tasked with managing the supply chain.

Sure, every OEM conducts small lot manufacturing and testing, but the problems occur when new models are put into full production. As such, having a strategic fabrication partner who can collaborate with the design team early in the planning process can be of great benefit to those tasked with managing the supply chain.

A supplier-partner can share insights that have been gleaned from their other customers – something which is difficult to achieve when production and assembly are solely performed in-house.

For starters, this level of interaction can help to identify potential trouble areas in a design, thus reducing the need for change orders in the future. In addition, a supplier-partner can share insights that have been gleaned from their other customers – something which is difficult to achieve when production and assembly are solely performed in-house.

Value Add 3: Testing

It’s one thing to help an OEM put together an assembly, but it’s something completely different to assist in testing. This is a huge opportunity for the OEM and the supplier-partner, as doing so not only reduces lost time when an issue is found, it can also save money – in some instances hundreds of thousands of dollars per year.

It’s simple to see how having a strategic partner conduct tests on assembled products can save time; after all, they are not shipping a problem to your warehouse where it might sit for days undiscovered. But what’s more interesting is how this time savings can be turned into dollars in the bank.

For starters, there is the elimination of non-compliant inventory, which even occurs in zero-defect environments. This can lead to massive savings. Beyond this, there are the costs associated with shipping and returning non-compliant inventory as well as the administrative hours tied to processing payments and performing and documenting tests.

These lost hours can be used to help the organization increase its competitive advantage rather than babysitting quality. Sure, you won’t be able to eliminate these lost hours completely, but the implementation of a thorough post-assembly QA test plan with a supplier-partner can reduce the number of hours tied to the administration of quality-related issues – many of which are not even counted today.

Beyond the savings, such a plan will instill a sense of ownership throughout the supply chain. Compare this type of plan to one in which a supplier-partner only worries about meeting their full line-item delivery metrics with little knowledge or concern for how the parts they are making will fit into the broader assembly.

Value Add 4: Logistics

Today’s supply chains are complicated affairs with parts for some builds being sourced from all over the world. Even when the assembly is “local” there can be complexity. An example of this is how some auto parts assemblies hopscotch between Detroit, Michigan and Hamilton, Ontario.

For OEMs seeking sanity, one option can be to utilize the assembly capabilities of their metal fabrication partners. Such an approach creates a production hub and simplifies logistics requirements, as the OEM is only receiving a finished assembly as opposed to separate parts that may require further transport.

Putting It All Together

Manufacturing in a global economy is competitive. One way in which OEMs can gain advantage is to leverage the capabilities of their strategic partners. In the case of metal fabricators, this can include assembly as the value-add to go well beyond freeing up production space.

If you are considering working with a strategic metal fabricator to assist with assembly, then you will want to keep the following points in mind:

- How will this help to simplify production? Sure, you are moving some of the production to a separate facility, but what are the measurable gains?

- What is the plan to improve collaboration with the design team? All too often design flaws make their way into production. There needs to be a plan to ensure adjustments are made in a timely manner.

- What is the QA plan, and how will it fit with your overall Quality Management System? Testing is great, but it needs to support the quality targets of the organization.

- How will creating a production hub simplify logistics? While the answer might seem obvious, the details matter.

Sourcing your metal fabrication across multiple suppliers is a major drain on your budget, but it doesn’t need to be that way. See how Miller’s integrated mechanical assembly solution can help you save both time and money.

Value Add 1: Simplified Production

Value Add 1: Simplified Production