Miller’s Environmentally Friendly Manufacturing Practices Contribute to a Sustainable Future

August 21, 2023

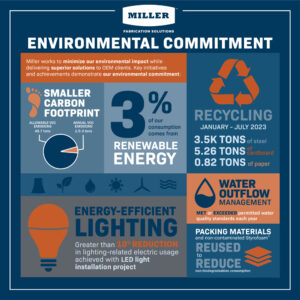

Like many companies, Miller Fabrication Solutions increasingly recognizes the importance of following sound environmental practices. We consistently work to minimize our environmental impact while delivering superior solutions to our OEM clients.

Here are key initiatives and achievements that demonstrate our environmental commitment:

Smaller Carbon Footprint

Our gas usage, VOC and carbon emissions data illustrate our dedication to reducing our carbon footprint. While our emissions permit allows for the release of 49.7 tons of VOC annually, for example, our use of powder coatings limits our emissions to just 2.5 to 3 tons. Our successful efforts to reduce emissions is testament to our ongoing sustainability efforts.

Embracing Renewable Energy

Whenever we can reasonably do so, we harness energy from renewable sources to fuel our operations. We have established a long-term agreement with our energy provider to ensure a steady supply of renewable energy, which currently accounts for approximately 3% of our consumption.

Water Outflow Management

Preserving the quality of water resources is important to us. At all our facilities, we hold stormwater release permits and collect the required runoff samples twice a year. These samples undergo rigorous third-party laboratory analysis, and the data is reported to the Pennsylvania Department of Environmental Protection (PA DEP). We consistently meet or exceed the water quality standards outlined in our permits, reflecting our commitment to maintaining clean water outflows.

Effective Recycling Programs

Miller has implemented robust recycling programs to reduce waste and promote sustainability. In 2023 alone, we have to date recycled an impressive 3,515 tons of steel, 5.26 tons of cardboard and 1,640 pounds of office paper. Additionally, we prioritize the reuse of non-contaminated Styrofoam and packing materials, thereby reducing the consumption of these non-biodegradable materials.

Environmentally Friendly Coatings and Chemicals

We are dedicated to using environmentally friendly paints and chemicals in our manufacturing processes. Prior to purchase or delivery, we thoroughly review all coatings and chemicals to ensure compliance with the stringent environmental standards set forth by the PA DEP. Our commitment extends to monitoring and reporting the use of these substances, including VOCs, carbon dioxide and other potentially harmful compounds. By adhering to these standards, Miller helps ensure the well-being of our employees, our communities and the environment.

Energy Efficiency through LED Lighting

To achieve greater energy efficiency, we completed an LED light installation project across all our facilities. This initiative has resulted in a greater than 10% reduction in lighting-related electric usage. Not only are we saving energy and reducing costs, but also the improved lighting enhances the overall work environment, contributing to quality and employee safety.

Meeting European Standards

Parts we produce for some customers are required to meet European standards. We meticulously review all chemicals to ensure compliance with these regulations, which are often stricter than U.S. standards. This commitment enables our customers to meet their environmental responsibilities and sell their products in Europe and the United States.

Miller’s efforts reflect our dedication to stewardship and environmentally friendly manufacturing practices. From minimizing carbon emissions and embracing renewable energy, to rigorous water management and effective recycling programs, we are committed to responsible practices that contribute to a more-sustainable future.

You Might Be Interested In

Corporate

March 12, 2025

Pam Elkin: A “Miller Lifer”Corporate

December 16, 2024

Investing in Our People: Miller Reinstates Weld School