How To Mitigate OEM Supply Chain Risks With Your Fabricator

December 4, 2015

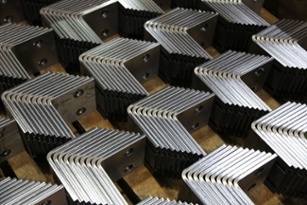

Few OEMs today manage all of their custom metal fabrication, welding, machining, finishing and assembly processes in-house. If you’re one of these few, you may have intentionally set up these processes in order to avoid supply chain risks. The reality is, however, that OEM supply chain vulnerabilities will always exist, with or without a metal fabrication partner. You simply need a way to deal with those risks specific to strategic relationships.

Few OEMs today manage all of their custom metal fabrication, welding, machining, finishing and assembly processes in-house. If you’re one of these few, you may have intentionally set up these processes in order to avoid supply chain risks. The reality is, however, that OEM supply chain vulnerabilities will always exist, with or without a metal fabrication partner. You simply need a way to deal with those risks specific to strategic relationships.

For example, late deliveries may cause your production line to shut down, or you might have to spend extra time reporting nonconformances if your partner lacks strict quality standards.

Instead of dwelling on potential issues that may arise in the future, the key is to take proactive steps to prevent them. You need to find a dependable metal fabrication partner that combines long-term planning with the flexibility necessary to address the unexpected.

To start, your partner should offer complete transparency, collaborating with you to understand your processes while providing visibility into its own onboarding, planning and account management. You must also have a clear understanding of your supply chain costs.

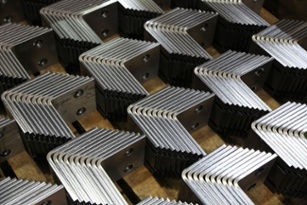

Your OEM supply chain is partly dependent on how quickly your partner can ramp up production when your demands increase. While the weaknesses of some partners are often exposed when faced with unexpected order requirements, a more strategic and trustworthy partner has an established infrastructure to keep pace with your growing needs.

Solutions To Reduce Supply Chain Risks

To manage supply chain risks, you should consolidate your vendor base so that your most reliable partners manage more of your metal fabrication spend. After all, optimizing production for a steady flow of inventory is their area of expertise. Reliable partners should have a proven track record of meeting high demand and intricate requirements.

The dependency on fewer partners can allow you to focus your attention on other areas, such as research and development, supply chain efficiency, and sales efforts.

Partner Approaches To Mitigate Risk

Some OEMs dedicate cash toward holding more inventory to reduce their supply chain risks. Better yet, leverage your partner’s inventory control and management solution so that a buffer stock may be maintained to fulfill extra orders rapidly.

The right metal fabricator collaborates with you to optimize your supply chain integration. By understanding your fabrication approach, spend, preferred materials and associated suppliers and other requirements, your strategic fabrication partner can assist with the appropriate manufacturing and value-added solutions to fit your needs while mitigating your risk.

Supply chain risk is a painful reality, but you don’t have to face it on your own. By seeking a true strategic partner to serve as your metal fabrication “arm,” you can secure your supply chain for future growth.

You Might Be Interested In

Industrial Fabrication

December 17, 2018

The Making of a Manufacturing ComebackVA/VE

July 16, 2018

How Your Fabrication Partner Can Add Value to R&D