3 Ways An OEM Partner Practices Inventory Control To Improve Reliability

August 11, 2017

Let’s say the unexpected happens: When you start production on a piece of equipment, you realize you don’t have the necessary parts.

You would probably go to your metal fabrication partner knowing that it keeps extra parts in stock for emergencies. But if your metal manufacturer’s inventory is inaccurate and it doesn’t have the parts you need, a small problem suddenly becomes a nightmare.

The right fabrication partner improves metal parts inventory reliability in your supply chain through the following practices:

1. Sales And Operations Planning

A proper sales and operations planning process enables your partner to take forecasts and evaluate how it wants to run production to accommodate demand. This is how your metal manufacturer should decide on inventory levels.

Your fabrication partner should allow for fluctuations in inventory to level out labor.

For example, some of your partner’s customers may require a heavy level of production in the first half of the year but be light in the second half of the year.

Your partner can’t produce everything in the first half of the year without asking employees to work excessive overtime, so it should start producing ahead of schedule in the late summer through early winter. Not only does this ensure customers get their parts on time, but it reduces labor costs by minimizing overtime.

Once a month, your partner gathers all sales forecasts and meets with key management to make the appropriate decisions on inventory levels.

Forecasts often evaluate a 12-month period, even if your partner only schedules for the next six months, so it is known what to expect down the line. This helps your partner make optimal personnel and labor decisions.

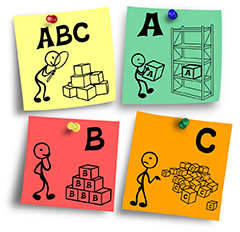

2. ABC Inventory Analysis

At the component level, the right fabrication partner manages inventory based on the ABC approach of handling safety stock, which is the set of parts your partner keeps in stock for emergencies.

The first decision your metal fabrication partner makes is whether a part is a stock item or non-stock item.

Each stock part is assigned an A, B or C rating based on its value. For example, if an item is an A, your partner may keep a week’s worth in stock but produce it regularly.

B parts may be produced every month, and your partner may keep two months of inventory in stock. Your partner may keep three months of a C part on hand but produce it less often. Because C parts tend to be a lower dollar value, your supplier can afford to carry more of them in inventory.

To keep track of inventory, your partner should practice robust cycle counting.

3. Pervasive Company Buy-In

Buy-in to optimized inventory management must be pervasive across your partner’s workforce. At first, some individuals may not trust the process. But once your supplier fine-tunes its inventory control, everyone from employees on the shop floor to supervisors and salespeople can realize the benefits.

Your partner experiences less chaos, for one. If you should want to increase product lines, your partner won’t be maxed out.

Plus, your metal manufacturing partner won’t have to hire as often to keep up. Its response to rising demand is no longer, “We’ll get back to you.” Instead, your manufacturer simply asks, “How many parts do you need?”

Once your fabrication partner masters proper inventory control, it can deliver a reliable, steady stream of parts to fuel your production line. Your company’s growth path is more straightforward without supply chain uncertainty.