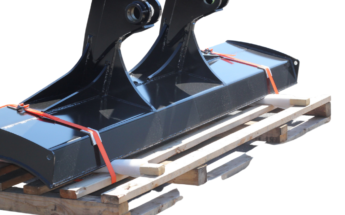

Excavator Blade

Complex projects represent the very challenges on which Miller Fabrication Solutions thrives.

This fact was demonstrated when an innovative, major Original Equipment Manufacturer (OEM) in the heavy construction industry turned to Miller for the ongoing manufacture of a hydraulic excavator blade. The blade includes three sub-assemblies, a custom paint color and multiple metals that, coupled with its assembled size that spans almost 2700 mm (110 inches) in width – make it a particularly challenging part to produce. Because of the product’s intricacies, the OEM’s existing supplier consistently had trouble meeting scheduling and cost targets.

Collaboration By Design

After determining manufacturability based on the customer’s design specifications and drawings, the teams at Miller engaged in a deeply collaborative process that included adjustments to the initial material cutouts to aid assembly and machining. Leveraging its extensive experience, Miller’s engineering team seamlessly:

- Identified and developed additional drawings that were necessary to assist the assembler in attaching the blade to the assembly.

- Created drawings and processes for bending the blade from flat to curved.

- Developed drawings and processes for precision-machining parts at various stages using state-of-the-art Amera Seiki and KBN equipment.

Once protypes were approved, production was initiated with regular, in-process inspections. Miller machines the main blade arm to the OEM’s specified thickness. For the first sub-assembly, components for the blade’s right and left arms are laser-, oxy- or plasma-cut, depending on their required thicknesses. Miller also follows the welding and polishing sequence designated for the blade arms and assembles the right and left arms as the second sub-assembly.

Sub-assembly of the blade comprises two processes. After individual components are cut, the blade’s arms are positioned and tacked to the blade, followed by positioning and tacking of the gusset plates. The blade’s interior and exterior are welded before the arms ultimately are attached to the blade.

Paint Pivot

Although Miller met the OEM’s paint process specs and audit, powder coating was rendered an unviable option due to the cross-sectional thickness of the part. The finishing solutions offered by Miller also include “wet” coatings, so this ready alternative capability enabled a quick, in-house pivot to a metal liquid coating. After blasting the part, Miller applies a 2-millimeter paint thickness using a zirconium chemical conversion coating. Cutting edges, which are sourced through the OEM’s parts supplier, are then bolted on by Miller team members.

The excavator blade created a unique shipping challenge as well, as its edges extended beyond a standard-sized pallet and posed a risk that the part could be scraped or otherwise damaged during transport. Miller sourced a larger pallet and worked with the OEM’s logistics partner to arrange appropriate shipping to ensure no damage is incurred in the process.

Simplifying the Complex

After meeting production and quality specifications, Miller maintains load-level inventory according to the OEM’s forecast. Regular reviews are conducted to discuss ongoing performance, potential revisions and other opportunities to help the OEM meet business unit and corporate goals and objectives.

Find out how Miller can serve as your strategic supplier-partner for your most complex components and assemblies – schedule a consultation with a heavy fabrication expert at Miller Fabrication Solutions today.

You Might be Interested in

Construction

April 14, 2020

Value Chain Opportunities in ConstructionConstruction

February 23, 2018

Constructing Your Smart Supply Chain Network